Airfoil Design Equals Better Overall Performance

Mechanical engineers who are searching for reliable components within an HVAC system for commercial projects will often do research to determine the best possible products to be used.

While turning vanes are a small component within the overall system, they can play a vital role in reducing noise while increasing efficiency throughout the system.

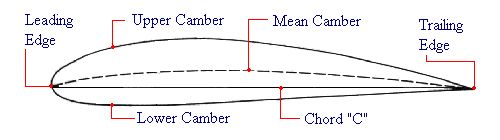

With Aero Dyne Turning Vanes, the vane’s airfoil design reduces generated sound power and relative pressure loss to their lowest attainable levels.

These vanes were initially designed this way to create a product that was “better than the standard requirement” and could be used specifically on projects that demanded better efficiency and performance – commercial projects like hospitals, educational buildings at colleges and schools and certainly in performing arts centers.

Aerodynamics at Work

The precise aerodynamic turning vane design allows the greatest steadiness of airflow through the cascades, eliminates breakaway of flow from surfaces on the suction side, provides velocity distribution to its greatest possible uniformity, and maintains a consistently high-degree of deflection accuracy.

Our vanes go through 17 points of roll forming precision using one piece of galvanized steel for the most positive rigid fit possible.

The design geometry adapts perfectly to all duct sizes, regardless of the inlet and outlet dimensions of the duct elbow, thus eliminating the need for multiple vane sizes.

Get a Turning Vane Sample Sent Directly to You

Curious about how our airfoil designed turning vanes look, feel and work? We’ll be happy to send you a Free Sample and Engineers Kit. Just call 800.522.2423 or click this link to fill our our contact form.