High Efficiency Profile (H-E-P) Turning Vanes

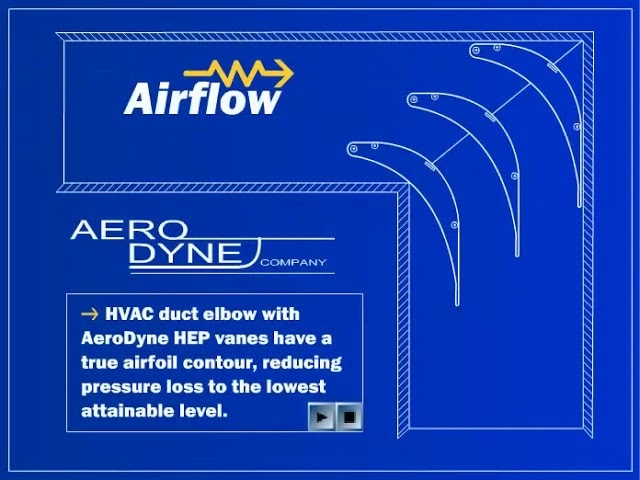

The High Efficiency Profile (H-E-P) Turning Vane and Rail System is used in HVAC systems to smoothly redirect airflow within ductwork, by minimizing turbulence and pressure loss, resulting in more efficient air distribution and reduced noise levels, often specified for projects requiring high performance airflow like hospitals and entertainment centers.

Based on results from the ETL Testing Laboratories, Inc. report no. 48037, Aero Dyne H-E-P Turning Vanes are certified for performance. The High Efficiency Profile design lowers relative pressure loss and reduces generated sound power to the lowest level attainable. Our design geometry adapts perfectly to all duct sizes, eliminating the need for two different vane sizes in the system. No other Turning Vane provides comparable quality, structural integrity, and performance for commercial HVAC installations.

Product Design Features

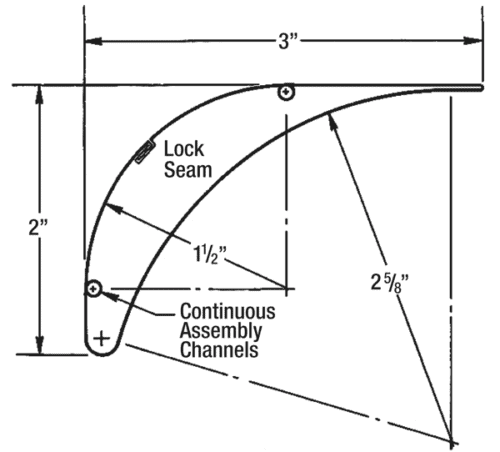

H-E-P Turning Vanes: 3″ Radius Airfoil blades by a 17-point roll-formed process using one piece of 27GA HD G60 Galvanized steel. Pre-cut /packaged in 10 ft. lengths sold 20 pieces per carton (200 ft. per carton).

Cuts are perfect, maximizing usable product from every 10 ft. piece.

No other product provides comparable quality, structural integrity, and performance.

- The generated sound power level does not exceed 54 decibels in band 4 at 2,000 FPM-duct 24 x 24

- Smooth-rounded entry nose and extended trailing edge

- No sharp leading edges to collect debris

- Manufactured in the USA

- Product guaranteed against defective material

Product Description

- Airfoil Blade: 17-Point roll-formed process using one piece of 27GA HD Prime Carbon Galvanized steel, furnished in 10 ft. lengths

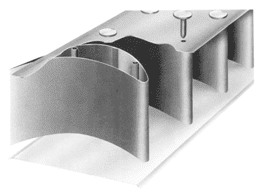

- Vane Rail: 24GA HD Galvanized steel, assembly slots located on design center spacing of 2.4”, furnished in 100 ft. coils

- Fasteners: Ring Shank style screws fasten into continuous channels inside the blade, no annoying rattle, no detaching, no reinforcing rods necessary

Installation Guidance

- Cut turning vane and rail to specified required length.

- Align internal vane tubular channels with the pre punched slots on the rail.

- Fasten the vane to the rail with provided nails using a palm nailer or hammer. Attach the side rail to both top and bottom of the vane..

Have Unequal Elbows? H-E-P Turning Vanes can be adjusted easily to the proper angle of attack, regardless of the inlet and outlet dimensions of the elbow

- A narrow strip (approx. 3/4 inch) is sheared from the center of both top and bottom side rail pieces.

- Vanes are attached to rails by the usual method of driving fasteners through the slots.

- All of the vanes in the assembly then move together as the correct alignment is made for the elbow, maintaining the leading and trailing edges in an exactly parallel relationship.

Applications & Benefits

- Commercial Installations & Retrofits – Widely specified in healthcare facilities, schools, laboratories, entertainment centers, data centers, and wind tunnels where precision airflow and noise control are critical.

- Airflow & Acoustics – Reduces turbulence and noise while helping systems meet LEED and ASHRAE sound criteria, such as maintaining ≤45 dBA in classrooms or meeting strict noise levels in healthcare environments.

- Cost-Effectiveness – Saves operational energy by lowering system resistance, extends HVAC system lifespan, and often eliminates the need for complete ductwork replacement in retrofit projects.

Quiet Ducts Start Here, Start with Aero Dyne

Ready to improve airflow efficiency and reduce noise in your HVAC systems? Aero Dyne’s High Efficiency Profile (H-E-P) Turning Vane and Rail System is made for superior performance, long-term durability, and easy installation. Whether you’re working on new construction or retrofits, our vanes help you meet strict energy and acoustic requirements while lowering operational costs. Contact us today to see why contractors and engineers have continued to trust Aero Dyne for over 50 years.